GOTCHA

14 Weeks Team Project to Develop A More Sustainable Solution For Gashapon.

What is GASHAPON

-

Gashapon machines today are found in nearly every corner of Japan and are popular with all ages

-

More recently, Gashapon have also become massively popular with women and international tourists.

-

40 million tourists to the country by 2020

PROBLEM?

-

‘An average of 840,000 Twisted Egg shells are discarded each month.’

-

‘Within 2,000 people interviewed , nearly half said they played with the Twister, 60% said they discarded toys or accessories after taking them out of the Gashapon Machine, less than 1% returned them to stores for recycling.’

TIME TO REDUCE THE IMPACT ON THE ENVIRONMENT!

TRIP to LITTLE TOKYO

RESEARCH

Team member: Katherine Yao (left) & Sylvia Wang (right)

Step 1:

Insert the coins

Step 2:

Turn the knob

Step 3:

Get your Gashapon capsule

Step 4:

Pop open!

How

to

Play

One of the biggest companies that produce Gashapon

-

A Japanese toymaker and a producer of many plastic model kits as well as a former video game company.

-

Bandai has many well-known animation brands. The most well-known is Mobile Suit Gundam.

-

Started to sell Gashapon in 1977. Then promoted the market into a new high level.

Marketing Ideas

The unexpected

Arranged numerous machines in rows creating a visual impact in an unfamiliar environment.

Quality, low-priced items

The toy figurines are detailed, well made, quality products for only ¥200 (about US$2)

Offloading loose change

“Given that some 28 million overseas tourists visited Japan in 2017, we have since calculated that, each of them had spent ¥1,000 (about US$10) on these toys, sales would have reached around ¥28 billion. Thus, by giving tourists a chance to use up their Japanese coins on toys that cost only ¥200 each, we expected the capsule toy business to post solid sales.”

-Tokyo Airport

Social networks to the rescue

The more snapshots that appeared online, the more the products were promoted.

BENCHMARK PLACE:

Airport

USER PATTERN

LCA

CALCULATE

Polypropylene

Polycarbonate

ABS

Stainless Steel

Iron Casting

Steel Hot Rolling

Tin Plating

Colored Pigment

White Pigment

LD Polyethylene

Injection Molding

Compression Molding

Thermoforming

Packaging Film

Sealing Tape

Chipboards

Paper

Diesel

Water, Ground Water

Truck

Air Freight

Ocean Fright

Train, Regional

China High V

Paper, Landfill

Chipboard, Landfill

Paint, Landfill

PP, Landfill

PE, Landfill

Thermoset Plastic, Landfill

Stainless Steel, Landfill

OKALA SCORE

BILL OF MATERIAL

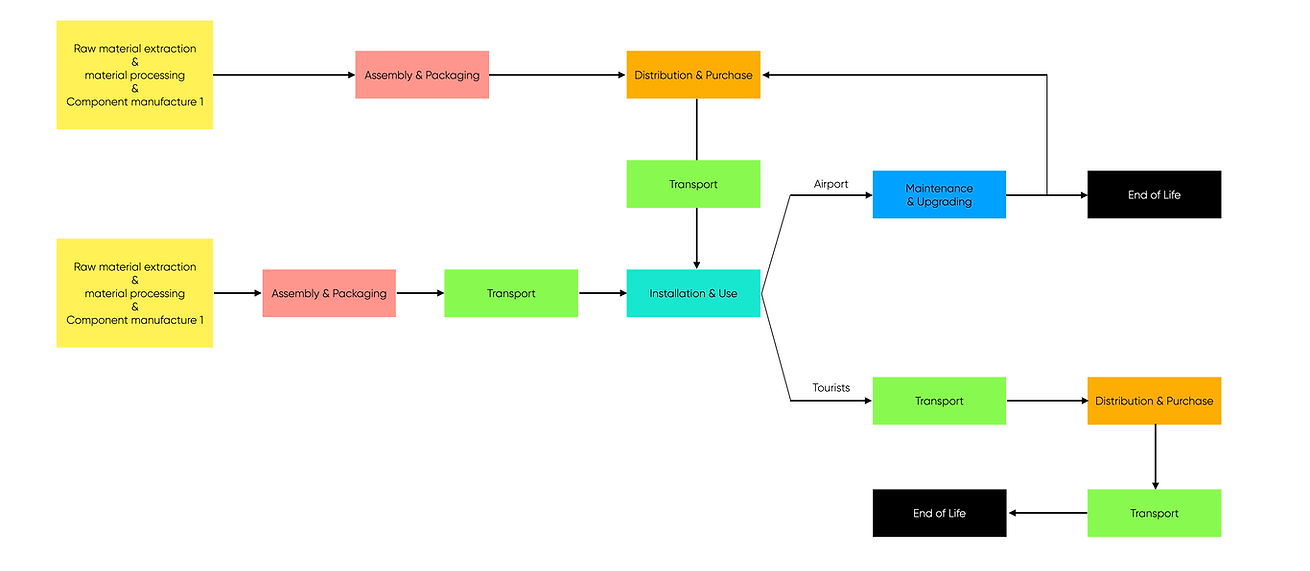

From the beginning to the end, there are more than 33 types of material and process is required for the Life cycle.

The manufacturing process begins with raw material extraction and processing, assembly and packing, installation, and use.

The map is split here to show the two different directions.

The top part represents the retailer, the bottom part represents the customer of these machines. Each of these steps will also need a transportation stage in the middle.

OKALA SCORE

CALCULATIONS

After applying all the calculations, the final result turned out with these numbers:

WHAT WE CAN DO

REDESIGN SYSTEM

IDEATIONS

Capsule

Machine

System

GOALS

#1

Reduce the amount of plastic used in the process of production.

Strategies to achieve this goal

1. Rematerialized

2. Dematerialized

#2

Reduce the impacts of these required plastics.

Strategies to achieve this goal

1. Completely replace materials

2. Use of recycled plastic

3. Reduce the amount of the required plastic

#3

Reduce the time of transportation required in the refill process.

Strategies to achieve this goal

1. Completely replace materials

2. Redesign the packaging and storing process

STEP 1

CAPSULE

By changing the form and the color of the shell, the capsule does not need to add color pigments to the raw materials.

By doing this, it is reducing the material needs and reaches a 10 % volume saving.

The shell remains the same structure as the old ones. It can use the old manufacturing process, to prevent the energy and material waste from developing a whole new production line.

The pattern on the shell also makes it easier for the users to grab on the capsules to twist open or grab open.

STEP 2

MACHINE

Open the upper lid to fill in the capsules. The new design could hold 48 capsules while the old version holds 32 capsules at a time.

By enlarging the inventory space of the machines, it would help reducing the transportation needs of the new gashapon balls.

How

It

Works

Following the branding language of Bandai Company to redesign the apperience of the machine.

STEP 3

RECYCLE SYSTEM

HOW IT WORKS

By creating this huge digital wall with these locking puzzle sets, after the users took out their toy in the capsule they can simply put their unneeded shells on these locks.

The area will light up and show a puzzle part of a bigger image.

WITH THIS SYSTEM

USER PATTERN:

CUSTOMERS/

TRAVELLER

USER PATTERN:

AIRPORT STAFF

ORDER

FILL

SET UP

COLLECT

RE-ORDER

RECYCLE

DO THE MATH

COMPARISON

LCA

CALCULATE

RESULT